Clemă de ridicare CD cu certificat CE

1) Before and after each use, check all parts for abnormal conditions, such as cracks in the welding seam of the clamp body. Deformation of holes or shafts and scratches on rotating parts. Rust and damaged jaws, etc.

2) After the label is lost, it should be replaced in time to avoid incorrect use.

3) The wrong storage place should prevent rust and damage to the painted surface of the cross clamp.

4) When not in use for a long time, grease should be applied to all movable parts, and the area parts should be painted.

5) The user is not allowed to change the structure of the vertical clamp at will.

Descriere produs

Informații despre produs:

Aplicație:Ridicare verticală a plăcii de oțel.

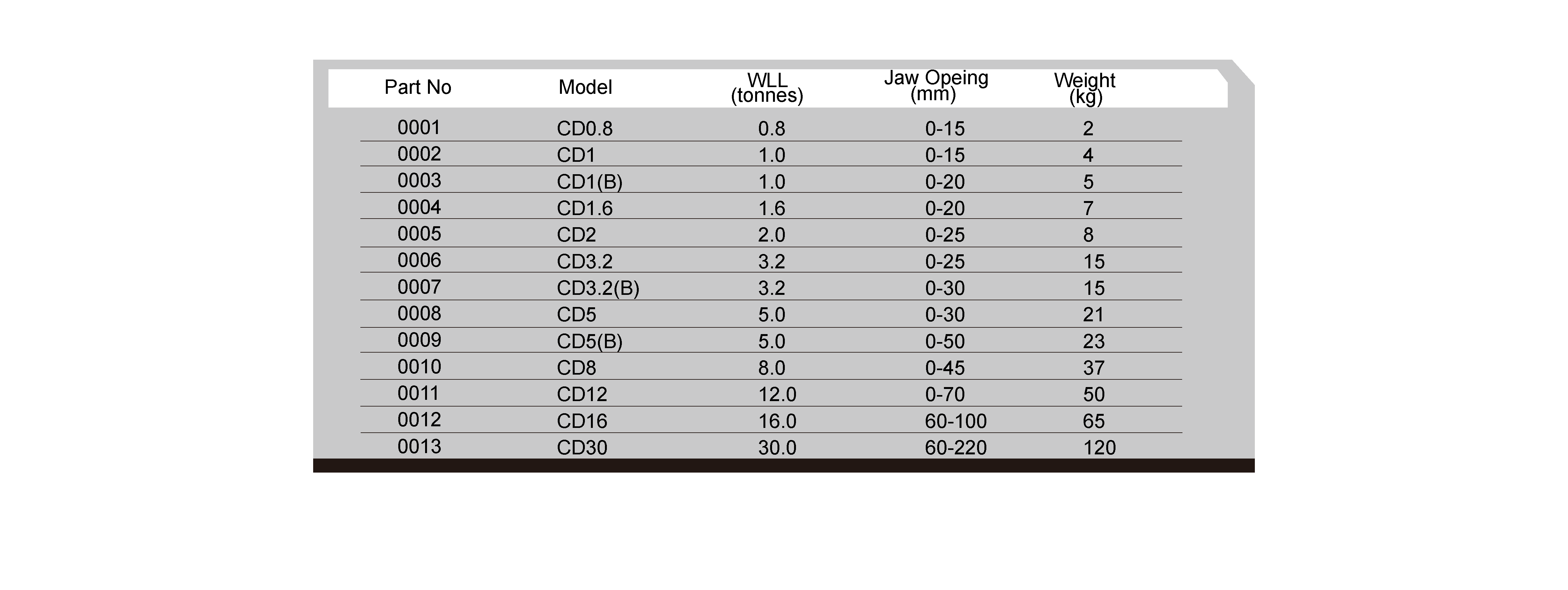

Interval de încărcare:0-12 tonă

Pentru testare se folosește o bucată de clemă,și o bucată sau 2 piesele sunt recomandate pentru operația de ridicare.

Plăcile multiple nu pot fi ridicate,Ridicați o singură bucată de clemă o dată. Ridicați pârghia de blocare pentru a strânge arcul de blocare atunci când este sub încărcare. Coborâți pârghia de blocare pentru a slăbi arcul de blocare,când puteai descărca.

Obiectul încărcat nu trebuie să atingă nimic în timpul funcționării. Încărcarea excesivă este interzisă. Când funcționează,supraîncărcarea este interzisă.

Sarcina testată este 2 timpii de sarcină de lucru.

Cu arc de blocare în starea de nefuncționare a clemei,dispozitiv de blocare merge în natură step-up,pune obiectul în clemă,puterea devine sporirea proporției.

Durabil durabil,operare usoara.

Precautions

-Only one steel plate can be lifted by vertical lifting at a time.

-The following situations are prohibited during use.

(1) If there is a serious tilt after lifting the steel plate, the lifting clamp should be re installed.

(2) The steel plate does not reach the bottom of the vertical clamp when the clamp is installed, so that only part of the steel plate is stuck by the vertical clamp after lifting the steel plate.

-During the lifting process, the steel plate that is forbidden to be lifted is subject to collision and impact.

-The lifting process should be as stable as possible, and it is strictly forbidden to stand underneath or pass over objects.

-The surface hardness of the suspended steel plate shall not be greater than HB220. Vertical clamps are not suitable for hoisting stainless steel plates. 10) No oil stains are allowed on the surface of the hoisted part of the steel plate.

scrapped

When one of the following situations occurs, the parts should be replaced or scrapped

1) When the wear height of the jaws and the support platform reaches 10% of the original height;

2) When two teeth are chipped or broken;

3) When the wear of the clamp shaft reaches 25% of the original diameter;

4) When the pliers shaft or pliers body deforms to 1.5% of the original size;

5) The overall movement of the horizontal clamp is not flexible, and it is still not flexible after adding lubricating oil to each sliding part.