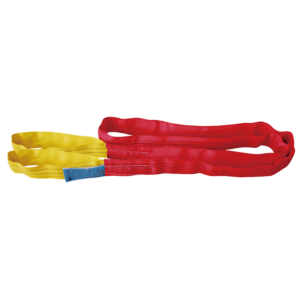

1T-10T Purple or Other Color Round Sling 100% Polyester Flat Webbing Sling Used in Shipping Mining OEM ODM Supplier

Round webbing sling, also known as a circular strap or endless suspension, is a device that lifts up and curved for it for safe lifting, reduced and mobilized heavy loads.

It is made of a strong and durable webbing material (usually polyester fiber, aimed at the multi -functional and flexible solutions provided by various enhanced applications).

Product Description

This is the description of the round woven strap suspension:

Structure: The round webbing sling is made of a continuous ring of high -strength synthetic webbing materials. This cycle seamless suture to form a circular shape. Bands are usually made of polyester and other materials. The material has excellent abrasion resistance, ultraviolet exposure and various chemicals.

Color coding: round webbing sling usually have different colors, and each color corresponds to specific load capacity. This color coding system can help operators quickly determine the appropriate hanging cable that is suitable for improving tasks.

Load capacity and security information: Each round webbing sling is usually marked with load capacity information, security guidelines and other related details. This information is essential for ensuring safety and appropriate use.

Soft and soft: the softness and flexibility of the webbing material make the round webbing sling consistent with the shape of the raising load. This flexibility helps to evenly allocate the load, thereby reducing the risk of load damage and ensuring safety improvement.

Multifunction: round webbing sling can be used for various improvement configurations, including vertical, screws and basket hooks. This multifunctional nature makes it suitable for different types of loads and improvements.

Starting focus: The round webbing sling has multiple focus along its length. These points provide options for adjusting the length of the suspension and creating the appropriate weightlifting configuration according to the load shape and weight distribution.

Soft load: The smoothness and non -loose nature of the webbing material are gentle on the surface of the lift. This is particularly beneficial to mention delicate or fragile objects.

Lightweight and portable: round webbing sling is light and easy to transport, making it a practical choice for applications with important mobility.

Reduced the risk of damage: the design and construction of a round webbing sling help to minimize the risk of damage load and the suspension itself. This can save costs by extending the life of the suspension and load.

Cost -effective: round webbing sling are usually more affordable than other types of lifting equipment, which makes them an effective choice of economic choices in various industries.

Drug resistance to chemicals and moisture: Polyester woven belts used for round suspension are resistant to many chemicals and moisture, which helps it durability and applicability of outdoor and industrial environment.

Easy to store: round webbing sling can be compact and stored, occupying the smallest space when not in use.

Although there are many benefits, it is important to note that the round webbing sling has load capacity restrictions and use guidelines. The operator should receive appropriate use of training and follow the suggestions of the manufacturer to ensure safety starting operations. Regular inspections and maintenance of suspension cables are also crucial to ensure its continuous reliability and security.

The main components of the round webbing sling include:

A round webbing sling, also known as a round webbing sling or endless hanging cable, is a simple and effective lifting and cable tool, which aims to safely lift and move the load. It consists of several key components, which together provide strength, flexibility and durability. This is the main component of a round webbing cable:

Belt material: The core component of the round webbing sling is the webbing material itself. It is usually made of synthetic fibers, and the most common is polyester fiber. Choose the ability of polyester high strength, abrasion resistance, and the ability to withstand various environmental factors (such as ultraviolet exposure and moisture).

Line: Switch the webbing material together to form an endless ring, thereby forming a characteristic circular shape of the suspension cable. This seam is essential for ensuring the integrity of the ring and preventing the opening of the webbing.

Color coding: Many round webbing slings are coded to show their load capacity. Different colors represent different weight restrictions. Users can quickly determine proper cables that are suitable for specific improvement tasks.

Wear protection: Some round webbing slings have protective functions, such as protective sleeves or lids to protect the suspenders from being worn and potential wear points. This extends the life of the suspension.

Improve point: The length of the circular hanging cable can be connected to the raising point at the starting point to lift the hook, chain or other hardware. These focus provides flexibility for creating different types of loads to create different types of loads.

Load tags: Load tags are usually attached to round webbing sling, providing basic information, such as rated capacity of suspension cables, use guidelines, security prevention measures and manufacturers’ detailed information. This information is essential for security and appropriate use.

Identity label: Label labels with unique serial numbers are usually attached to the round webbing sling. This label helps to track and maintain records of suspension inspections and use historical records.

Safe suture: The sewing design for creating endless circuit is used for strength and durability. High -quality stitching is critical to prevent suspension from failing under load.

Softness and flexibility: The softness and flexible properties of the webbing material make the round webbing sling adapt to the shape of the load and evenly allocate gravity. This flexibility helps to prevent suspension and load damage.

Inspection point: During the regular inspection, the operator should check the signs of the webbing material for wear, damage or wear. This is essential for the potential problems that determine the safety and reliability of the suspension cable.

Sling tags: In addition to identifying tags, some suspenders may also have a cable label, including load capacity information and instructions for usage. This label can help users quickly determine the capacity of the suspender.

Keep in mind that appropriate training on inspection and maintenance of circular ribbon suspenders is essential for ensuring safety during improving operations. Following the manufacturer’s guidelines and the industry’s best practice will help extend the life of the suspension and prevent accidents.

2.Why choose us

Quality and: Customers often consider high -quality woven belts, with bands and more

Load capacity: Ensure the capacity of the load of a round webbing sling. Task. Customers and customers also attach importance to their attention to functional functions

Multi -functional: The hanging cables that can be used and hooking are common, because they are favored because they are because they are

From: some customers are right, load, load, or other specific requirements. Companies that provide define definitions can be satisfied

Certification: Full confidence in compliance with the circular and security regulations to make the right harmony and security full of confidence

Price: Rather than and the price of the suspended cable seeking its value for customers and customers one by one, one by one

Brand: Customers and customers like to buy from a reliable brand brand brand brand brand

Customer: Provide excellent customers, including assistance, sale, after -sales service, and query

Warranty: Reliable policy covering defect failure makes customers assured of ensuring the quality of the product

Comments: Other or industry personnel are active and suggestions that can affect customers.

Availability: Production: Production and fast availability Delivery may be beneficial and beneficial

Environment: Some customers will be given priority and manufacturing

In the end, round webbing is selected and prioritized. Thoroughly thorough and thorough, compare research, compare and consider the functions of claims, or I will share these with customers and customers through materials

Advantage:

Circular woven cables (also known as circular hanging cables or endless suspension) provide several advantages to make them popular choices for improvement and cable applications. These advantages originate from their design, material characteristics and versatility. The following are some key advantages of the circular webbing cable:

Flexibility: The round webbing sling is highly flexible and adapts to the shape of the load. This flexibility helps to uniformly allocate loads, thereby reducing the risk of suspension and load damage.

Power and weight ratio: The round webbing sling is made of powerful synthetic materials (usually polyester), which usually provides high -intensity ratio. This means that the hanging cable is relatively light, and it provides a clear ability to improve.

Load distribution: The softness of the webbing material can prevent the concentrated stress point on the load. This feature helps to prevent damage to the load surface and improve the load stability during the weightlifting period.

Multifunctional in the hook configuration: The round webbing sling can be used for various lifting types, including vertical, sled, and basket hook. This versatility enables them to adapt to different load shapes and types.

Gently load: The smooth and non -scattered properties of the webbing material are soft or fragile, which makes the round webbing sling suitable for sensitive items.

UV and chemical resistance: Polyester woven for round suspension is resistant to ultraviolet rays and many chemicals, which can ensure their durability and performance in different environments.

Decrease in noise: Compared with the metal chain, the noise generated during the weightlifting process is small, which may be favorable in an environment where noise is very important.

Easy to store: The round webbing sling is compact and easy to store, and the smallest space is required when not in use.

Safety function: round webbing sling are usually equipped with security functions, such as load capacity indicators and logo labels of color codes. These functions help to ensure proper use and minimize the risk of accidents.

Cost benefits: round webbing sling are usually more cost -effective than other types of lifting equipment, which makes them economic choices for various improvements.

Duravity: High -quality polyester woven belts are durable, and the resistance and life of wear can help extend the life of the round webbing sling.

Ecological engineering processing: Due to its lightweight and ergonomic design, round webbing slings are easy to handle. This can improve the comfort of the operator and reduce the pressure risk of the weightlifting mission.

Non -conductive: Polyester woven belt is non -conductive, and it may be beneficial when the conductivity may constitute a safe risk environment.

Corrosion resistance: Unlike the metal chain, the round webbing sling is not easily corroded, making it suitable for use in corrosive or marine environments.

Non -training: Soft webbing materials will not scratch or damage the surface, making the round webbing slings very suitable for raising the finished or painted objects.

When choosing a round webbing sling, it is important to consider factors such as load capacity, application requirements and security regulations. Proper training in the use of suspension, inspection and maintenance is essential for ensuring safety lifting operations and maximum round webbing slings.

FAQ:

Q1. I want more styles, how to get the latest directory for your reference?

Answer: You can contact us through emails. We will provide you with the latest directory based on your information.

Q2. Can you add our own logo on the product?

Yes. We provide services to add customer logo. There are many types of this service. If you have this need.

Q3. What do your factory do in quality control?

Answer: “Quality is priority? We always attach great importance to quality control 1) Skilled workers are concerned about all details of the process of processing and packaging. 2) The quality control department is particularly responsible for the quality inspection in each process

Q4. What is the order?

you can tell us the model of the product you like, we will send you a quotation to you.