Product Description

Products description :

Hydraulic Drum Rotator/Manual Drum Lifter/Hand Drum Lifter

Safe drum dumping requires well-designed, ergonomic drum handling equipment to reduce risks of injury or property damage. Our this hydraulic Drum Karriers, drum dumpers combine incredible strength with simple drum handling by one person. It can help you lift, move, and pour plastic, fiber and steel drums, and also can provide controlled dispensing of your drums. With the feature of simple design and easy operation, this all-steel construction Hydraulic Drum Dumper is what you need to dump steel & plastic drums.

Key feature:

1.Hydraulic lifting: Adopting an efficient hydraulic system, can easily realize the lifting operation of the barrel to ensure the smooth flow of liquid.

2.Flip Function: An accurate flip design can flip the barrel 360 degrees to ensure that the liquid is fully mixed and improve work efficiency.

3.Safety Protection: Equipped with a safety lock mechanism to ensure safety during the turning process and prevent the barrel from sliding or becoming unstable.

Model:Hydraulic Drum Dumpers Drum Handle

Capacity:450kg

Max. lifting height:1600mm

Lifting weight:400kg

Minimum turning radius:1850m

Lift Mechanism:Articulated Lift

Running Mode:Moving

Carrying Capacity :Weight Level

Driven Type :Rack&Pinion

Feature:Explosion-Proof

Transport Package:by Container

HS Code:8431499900

Origin:China

Package Size:131.00cm * 90.00cm * 203.00cm

Package Gross Weight:175.000kg

Product details:

Product description 1

Antiskid Clamp:strong bite force durable, strong and not easy to fall off.

Product description 2

Detachable Axletree:Uniquely designed bearing system with easy mounting and dismounting.

Product description 3

Controllable Braker:Improved safety and flexibility in equipment operation, enabling operators to better cope with different work scenarios.

Product description 4

Flexible Steering :Easier steering and reorientation in different conditions.

Product description 5

Hoop Lock:Doubles the safety. fits the barrel body, and is equipped with a barrel support when it is pulled down. which is more stable when carrying the oil barrel.

Product description 6

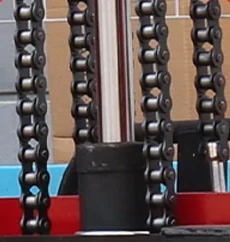

Sealed Cylinder:Use high-quality chains and integrally sealed hydraulic i-cylinders to prevent leak-age safely

Product Features:

1.Rugged: The Manual Lifting Drum Machine is manufactured using high-strength materials to ensure it is robust and able to cope with the demands of heavy-duty industrial environments.

2.Adjustable: Flexible design, suitable for different diameters and lengths of drums, with an adjustable lifting arm to meet a wide range of drum lifting requirements.

3.User-friendly operation: The equipment is easy to operate, and equipped with a user-friendly joystick, allowing the operator to easily master the equipment and improve work efficiency.

4.Safety: Safety is an important feature of manual drum lifting machines, which are equipped with sturdy support feet to ensure stability during drum lifting, as well as non-slip surfaces to reduce the potential risk of rolling.

5.Versatility: In addition to lifting drums, some manual lifting drum machines are also equipped with a tilt function, which allows the tilt angle of the drum to be easily adjusted to meet the needs of specific industrial applications.

Product Advantage:

1.Increased Efficiency: Manual drum lifters can quickly and easily lift heavy drums, increasing the efficiency of material handling and loading and unloading.

2.Reduced Labour Intensity: By using a manual drum lifter, the operator is not required to perform excessive physical labor, effectively reducing the labor intensity of the handling task.

3.Adaptable: The machine is suitable for a wide range of drums and can be adjusted to meet specific job requirements, providing wider applicability.

4.Space-saving: Thanks to its compact design, the manual lifting drum machine fits into limited spaces, providing a more flexible handling solution for industrial environments.

5.Low cost: Compared to some automated drum lifting systems, manual lifting drum machines are relatively low cost, making them an affordable option.

Our services:

1. Customised solutions: We offer customized solutions based on the specific needs of our customers. Whether it is for a particular operating environment, a specific type of goods, or other requirements, we can work with our customers to design and customize electric pallet trucks to ensure optimum performance and results.

2. After-sales service: We offer a comprehensive after-sales service, including equipment installation, commissioning, and training. Our professional technical team can provide equipment repair and maintenance services to ensure proper operation and extend the life of the equipment.

3. Spare parts supply: We offer a supply of original spare parts to ensure that our customers have access to high-quality parts when repairing and replacing equipment. We have a wide range of spare parts in stock and can supply the required parts quickly.

4.Technical advice and support: Our dedicated team can provide technical advice and support on electric pallet trucks. Whether it is about equipment selection, operating instructions, or maintenance advice, we can provide expert advice and solutions.

FAQ :

Q1: What is our factory product range?

We specialize in chain blocks, lever blocks, electric hoists, webbing slings, cargo lashing, hydraulic jacks, forklifts, mini cranes, etc. 2) Hoist Accessories: Load chain, wire rope, rigging, hook, pulley, and shackles.

Q2:How about a sample policy?

Welcome sample order. Please inform your detailed sample requirement, such as the quantity, capacity, chain, lift, and so on. If we have the sample in stock, the ship will be quicker. If we don’t have stock, please understand to wait for the produce. The express fee is charged by the shipping company. The sample fee and express fee are usually paid by a client, for special policies need to apply by the client and approved by our leaders.

Q3: How to order?

Please send us your purchase order by Email or Fax, or you can ask us to send you Performa Invoice for your order.

We need to know the following information for your order:

1) Product information: Quantity, Specification (capacity, lifting height, voltage, size, material, color, and packing requirement

2) Delivery time required.

3) Shipping information: Company name, Address, Phone number, Destination seaport/airport.

4) Forwarder’s contact details if there are any in China.

Q4: What are the payment terms for sample cost and order amount?

We accept the payment sent by West Union, D/P, D/A, T/T, or L/C at sight.