Product Description

Product description:

EB Webbing Sling is an important tool widely used in the field of lifting, lifting and transportation. It is made of high -strength, wear -resistant webbing materials, and is usually used for hanging heavy objects to replace traditional steel wire rope cables. EB Webbing Sling have become an indispensable equipment in the modern industry and construction industries because of their lightness, high strength, softness and durability. The following is a detailed description of EB Webbing Sling:

Part 1: Materials and structures of EB Webbing Sling

The main materials of the EB Webbing Sling are high -strength synthetic fibers, such as polyester fibers and nylon fibers. These synthetic fibers have excellent tensile strength and wear resistance, and can withstand the lifting of high loads and heavy objects. The webbing is usually woven from multi -layered fibers to form a solid structure to ensure its reliability and security.

Part 2: The characteristics and advantages of the EB Webbing Sling

Light and flexible: Compared with the traditional steel wire hanging cable, EB Webbing Sling is lighter and flexible, easy to carry and use. Its softness makes it easier for hanging in a small space or complex environment.High -intensity: EB Webbing Slings are made of high -strength synthetic fibers, which can withstand huge loads. It has excellent tensile strength to ensure that it is not easy to break or damage during the lifting process.Wear resistance: Synthetic fiber materials have good abrasion resistance, so EB Webbing Sling can also maintain good performance under frequent use and friction.Chemical corrosion: Compared with steel wire ropes, the EB Webbing Sling has stronger resistance to chemical corrosion and corrosive substances, increasing the service life.Non -conductivity: EB Webbing Sling are non -conductive, suitable for some special occasions, such as working near high -voltage electric fields to avoid accidents.Environmental protection and friendship: Compared with traditional steel wire hanging cables, EB Webbing Sling have less impact on the environment and more environmentally friendly in terms of production and abandonment.

Part 3

Construction industry: EB Webbing Sling are widely used in construction sites and used to hang steel beams, concrete components and other heavy building materials.Shipping industry: During the maintenance and loading of ships, EB Webbing Sling can be lifted safely and efficiently.Aerospace: EB Webbing Sling are also used in the aerospace industry for loading and unloading aircraft components and equipment.Mine and quarry: In the mine and quarry, the EB Webbing Sling is used to hang ore and giant rocks.Energy industry: In the process of energy equipment installation and maintenance, EB Webbing Sling are indispensable tools.

Part 4: The safe use and maintenance of the EB Webbing Sling

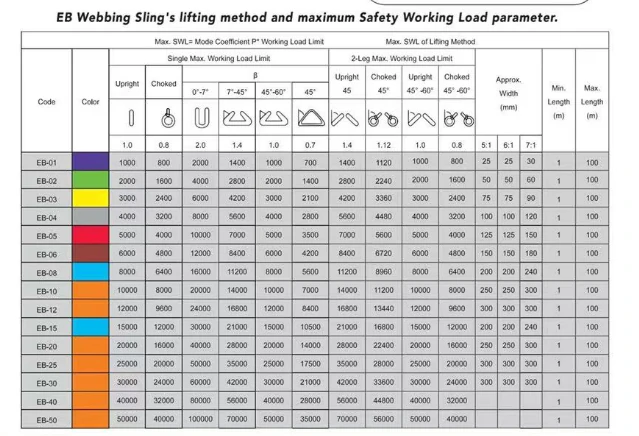

Reasonable use of loads: When using an EB Webbing Sling, the load must be reasonably selected according to its specifications and logo, and it must not exceed its bearing capacity.Regular inspection: EB Webbing Sling should be checked regularly to ensure no wear, cracks, damage or other defects.Avoid excessive bending: During use, you should avoid excessive bending of EB Webbing Sling to avoid damage to its structure.Prevent chemical corrosion: Avoid access to harmful chemicals with EB Webbing Sling to maintain its performance and life.Precautions for storage: The unused EB Webbing Sling should be stored in a dry and ventilated environment, away from direct sunlight exposure and humidity.

Summary: EB Webbing Sling is an excellent hanging tool, which has the characteristics of lightweight, high strength, wear resistance and chemical corrosion, and is widely used in industries such as construction, aerospace, aerospace, energy. However, during use, we must pay attention to safe use and regular maintenance to ensure their performance and life, and to ensure work safety.

The main components of the EB Webbing Sling include:

EB Webbing Sling is an important hanging tool made of high -strength synthetic fibers. The main composition is synthetic fiber material obtained by chemical synthesis or high -temperature and high pressure treatment. These synthetic fibers have excellent physical characteristics, including high -strength, abrasion resistance, chemical corrosion resistance and other characteristics, making EB Webbing Sling an indispensable equipment in the modern industry and construction industries. The main components of EB Webbing Sling will be described in a more detailed description below.

1.Polyester fiber:Polyester fiber is one of the common synthetic fibers in EB Webbing Sling. It is made of polytinyl glycolic glycol, and has high strength and good wear resistance. Polyester fiber is usually widely used in the inner layer of EB Webbing Sling to increase the tensile strength and bearing capacity of the suspension cable. In addition, polyester fibers also have good chemical resistance, so that they can also maintain stable performance when they are used in complex environments.

2.Nylon:Nylon fiber is another commonly used synthetic fiber material, which is also widely used in the manufacture of EB Webbing Sling. Nylon fiber is a high -intensity material, which has excellent wear resistance and can provide reliable support and protection during heavy objects. Its softness and durability make EB Webbing Sling easier to operate during the lifting process, and also reduces the degree of wear of the webbing itself.

3.PolyPropylene:Polypropylene fiber is a light -quality synthetic fiber, which is usually used for the protective sleeve or outer layer of the EB Webbing Sling. Although the tensile strength of polypropylene fiber is relatively low, it has excellent chemical corrosion resistance and waterproof performance, which can effectively protect the synthetic fiber of the inner layer from erosion from the external environment.

4.Polyramid (Polyaramid, such as Kevlar):Poofanamide fiber is a high -performance synthetic fiber with excellent strength and abrasion resistance, and it is also an important part of the EB Webbing Sling. Poofanamide fiber is commonly used to create the inner layer of a suspension or enhanced layer to provide higher tensile strength and bearing capacity. Due to its excellent performance, polyanamide fiber is widely used in hanging operations under high -intensity and special operating conditions.

5.Other auxiliary materials:In addition to the above main components, the manufacturing of EB Webbing Sling may also use some auxiliary materials, such as coating, protective layer, logo, etc. The coating can enhance the wear resistance and corrosion resistance of the web, while providing better frictional characteristics. The protective layer is used to enhance the durability of the webbing and enable it to use it in a harsh environment for a long time. The logo plays a sign of specifications and information on the webbing, which is convenient for users to choose and operate correctly.

Summary: The main component of EB Webbing Sling is composed of high -strength synthetic fiber materials, including polyester fiber, nylon fiber, polypropylene fiber, and polyfrinamide fiber. These synthetic fibers give EB Webbing Sling with excellent characteristics such as lightweight, high strength, wear resistance and chemical corrosion resistance, making it an important lifting tool widely used in various industrial fields. When using EB Webbing Sling, it is necessary to follow relevant safety specifications, check and maintain regular inspections to ensure its performance and service life, and to ensure work safety.

2.Why choose us

To choose a company’s EB Webbing Sling, you need to comprehensively consider multiple factors. The following is some possible reasons, explain why you choose your company’s EB Webbing Sling:

1.High -quality materials: The EB Webbing Sling of your company is made of high -strength synthetic fiber materials to ensure that the suspension cable has excellent tensile strength, abrasion resistance and chemical corrosion resistance. High -quality materials make the hanging cable more reliable and safer when hanging heavy objects.

2.Experienced manufacturing process: your company has rich manufacturing experience and advanced technology to ensure that EB Webbing Sling strictly controls the quality in the production process and ensures the stability and consistency of the product.

3.Diversified specifications and models: The EB Webbing Sling of your company provides a variety of specifications and models to meet different hanging needs. Whether in the fields of construction, ships, aerospace, mines, or energy, it can be found.

4.Professional technical support: your company provides professional technical support and service teams, which can provide customers with hanging plans and solutions to ensure the safety and efficiency of hanging operation.

5.Reasonable price: While providing high -quality products for your company’s EB Webbing Sling, it can also maintain a reasonable price level, enabling customers to obtain a value -for -money hanging tool.

6.Customer word of mouth and reputation: The company has accumulated good reputation and reputation in the cable industry. Customers have highly evaluated the company’s EB Webbing Sling suspension. This is an important reference factor for choosing your products.

7.Timely delivery and after -sales service: your company can deliver products in time and provide thoughtful after -sales service to ensure that customers get timely support and help in the process of using EB Webbing Sling.

In summary, the EB ribbon suspension of your company’s company is because of its high -quality materials, rich manufacturing experience, diversified product specifications, professional technical support, reasonable prices, and good customer reputation and reputation. These advantages make your company’s EB Webbing Sling the best crane solution and can meet customers’ various lifting needs.

3.Advantage:

As a modern crane tool, the EB Webbing Sling has many advantages that make it widely used in the industrial and construction fields. The following is the main advantage of EB Webbing Sling:

1.High -intensity: EB Webbing Sling are made of high -strength synthetic fiber, which has excellent tensile strength. Compared with the traditional steel wire cable, its strength is quite or even higher, and it can withstand heavier loads.

2.Light and flexible: Compared to the traditional metal cable, EB Webbing Sling is very light and flexible. Its weight is light, which is convenient for carrying and installation, making it more convenient to hang out in a small space or complex environment.

3.Wear resistance: Synthetic fiber materials have excellent abrasion resistance, so that EB Webbing Sling can also maintain good performance under frequent use and friction. This makes the lifetime life longer and reduce the frequency of maintenance and replacement.

4.Non -conductivity: The EB ribbon suspension is non -conductive and suitable for some special occasions, such as working near high -voltage electric fields to avoid accidents such as electric shocks.

5.Chemical corrosion: Compared with steel wire ropes, EB Webbing Sling has stronger resistance to chemical corrosion and corrosive substances. This allows it to maintain stable performance in some harsh working environments.

6.Low noise: Compared with the metal suspension, EB Webbing Sling is low in noise. This is especially important for working on noise -sensitive areas.

7.Easy to check: There is no rope stock structure on the surface of the EB Webbing Sling, so it is easy to check and discover the possible defects during use, which helps to find problems early and deal with it in time.

8.Environmental protection and friendship: Compared with traditional steel wire cranes, EB Webbing Sling have less impact on the environment and more environmentally friendly in terms of production and abandonment.

9.High security: EB Webbing Sling have been strictly tested and controlled during the design and manufacturing process to ensure its stable and reliable performance. This makes the hanging cable more secure and reliable in the hanging operation.

In summary, EB Webbing Sling has a series of advantages such as high strength, lightness and flexibility, abrasion resistance, non -conductive, chemical resistance, low noise, easy inspection, environmental friendly friendship and high security. These advantages make EB Webbing Sling become an ideal hanging tool in the field of modern industries and construction, which is favored and selected by more and more enterprises.

4.FAQ:

Q1: What exhibition did participate in?

Answer: Almost all professional exhibitions once a year, International Hardware Exhibition, China International

Occupational Safety and Health Commodity Expo.

Q2: How about the product? Can your product quality be guaranteed?

Answer: All our products are in line with CE, ISO9001: 2008, LA standard. In addition, we are proud of the complete test laboratory.All products will be checked and tested before delivery.

Question 3: How to pack products?

Answer: Generally, the seat belt is equipped with nylon bags, non -machine bags in carton/box.

Question 4: What is your payment period?

Answer: Usually T/T 30 % deposits in advance, 70 % before delivery.

Question 5: Can I become a distributor in my area?

Answer: As long as you have the marketing resources you are located, we are glad to cooperate with foreign distributors and provide it Corresponding service.